Efficiency is one of the most critical performance indicators in modern electric motors. A well-designed stator assembly directly impacts energy consumption, heat generation, torque output, and overall motor lifespan. When combined with precise manufacturing processes such as a motor stator winding machine, the design quality of the stator becomes a decisive factor in achieving high operational efficiency. Understanding how design choices affect performance helps manufacturers and engineers optimize motor systems for demanding applications.

Understanding the Role of Stator Assembly in Motor Efficiency

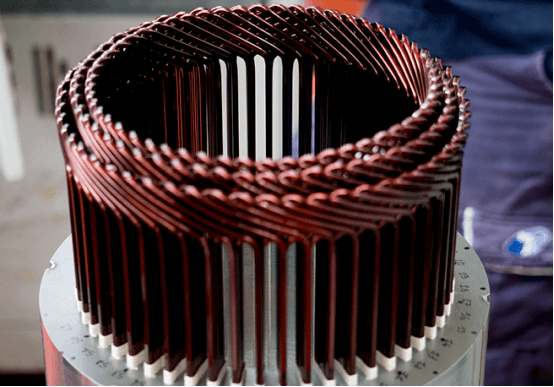

The stator is the stationary part of an electric motor responsible for generating the magnetic field that drives rotation. Its design determines how effectively electrical energy is converted into mechanical output.

Importance of Magnetic Field Optimization

Efficient magnetic field generation depends on uniform flux distribution. Poor design can lead to flux leakage, uneven magnetic density, and energy losses. Proper slot geometry and lamination alignment help maintain consistent magnetic flow, reducing inefficiencies.

Impact on Energy Losses

Inefficient stator design increases core losses, copper losses, and stray losses. These losses not only reduce efficiency but also raise operating temperatures, accelerating insulation degradation and reducing motor life.

Material Selection for Enhanced Performance

Choosing the right materials is fundamental to improving efficiency through stator design.

High-Quality Core Materials

Electrical steel laminations with low hysteresis and eddy current losses significantly improve efficiency. Thinner laminations reduce circulating currents, minimizing heat buildup and energy waste.

Insulation Materials and Thermal Stability

Advanced insulation materials with high thermal endurance allow the stator to operate at higher temperatures without performance degradation. Proper insulation thickness also improves slot fill while preventing electrical short circuits.

Optimizing Stator Slot and Winding Design

Slot and winding design plays a major role in electromagnetic efficiency and thermal management.

Slot Geometry and Space Utilization

Well-designed slots maximize copper fill factor while maintaining sufficient insulation clearance. Improved slot shape enhances magnetic coupling and reduces resistance losses.

Winding Configuration and Balance

Balanced winding layouts ensure uniform current distribution, reducing vibration and electromagnetic noise. Symmetrical designs help minimize torque ripple and improve smooth motor operation.

Reducing Heat Generation Through Smart Design

Heat is one of the biggest enemies of motor efficiency.

Improved Cooling Pathways

Proper stator design includes airflow channels and cooling paths that allow heat to dissipate efficiently. Reduced thermal resistance improves continuous operation capability without overheating.

Minimizing Electrical Resistance

Shorter conductor paths and optimized cross-sectional areas lower resistance. Reduced resistance directly improves efficiency by decreasing copper losses during operation.

Precision Manufacturing and Assembly Techniques

Design efficiency can only be realized when manufacturing processes maintain high accuracy.

Dimensional Accuracy and Tolerances

Precise alignment of laminations and windings ensures consistent magnetic performance. Tight tolerances reduce air gaps that can cause magnetic imbalance and losses.

Automation and Process Control

Automated winding and assembly processes improve repeatability and reduce human error. Consistent tension, placement, and layering of conductors contribute to uniform electromagnetic performance.

Enhancing Reliability Through Structural Design

Efficiency is closely linked to mechanical stability and long-term reliability.

Vibration Reduction

Proper structural support and secure winding placement reduce vibration. Lower vibration improves efficiency by preventing mechanical energy losses and reducing wear.

Long-Term Durability

A well-designed stator resists thermal cycling, mechanical stress, and electrical fatigue. Durability ensures that efficiency levels remain stable throughout the motor’s service life.

Quality Control and Testing for Efficiency Assurance

Testing is essential to validate design effectiveness.

Electrical Performance Testing

Resistance, insulation resistance, and inductance testing help identify inefficiencies before final assembly. Early detection prevents performance losses in finished motors.

Thermal and Load Testing

Thermal tests verify heat dissipation capability under real operating conditions. Load testing ensures that the stator performs efficiently across its intended operating range.

Design for Application-Specific Efficiency

Different applications demand different efficiency priorities.

Industrial Applications

Industrial motors often prioritize continuous operation and thermal stability. Stator designs for these applications focus on durability and consistent efficiency under heavy loads.

Energy-Sensitive Systems

In applications where energy savings are critical, stator designs emphasize low losses and optimized electromagnetic performance to reduce operating costs.

Conclusion

Improving motor efficiency starts with thoughtful design, careful material selection, precise manufacturing, and thorough testing. A properly engineered stator assembly minimizes energy losses, enhances thermal performance, and ensures long-term reliability when produced using accurate processes such as a motor stator winding machine. By focusing on design optimization at every stage, manufacturers can achieve higher efficiency, lower operating costs, and improved performance across a wide range of motor applications.